THE BOW-BOLT—Installation Instructions for New Construction

Please Read First

The Bow-Bolt has been tightened to the stop as you receive it. Please examine it before you loosen it or install it.

There is an “index” mark near the “half hole” in the edge of the flange. When the Bow-Bolt is tightened all the way to the stop, the marks on each half of the Bow-Bolt are lined up across the flange. It will take considerable force to loosen the Bow-Bolt to separate it while it is not installed in the bow, but it can easily be separated by hand when installed.

If you loosen it (to see how it works) before you install it, you will need two pair of large pliers or Vise Grips to do so, but BE SURE TO RETIGHTEN IT TO THE STOP BEFORE INSTALLING. Otherwise, the two halves of the bow will not line up properly when twisted together. Also, when using the vise grips on the female part of the Bow Bolt, clamp near the end away from the flange to avoid distorting it.

Be sure to clean all surfaces thoroughly with Acetone before installing. This includes the outer surface of the Bow-Bolt, the surfaces of the holes drilled in the riser and the surfaces that receive the micarta. Be sure that all surfaces have had time to dry thoroughly before applying the epoxy, and when you apply the epoxy (Smooth-on or MT-13 Recommended), be absolutely certain that all surfaces are thoroughly coated. It is a good idea to use your finger (with latex gloves on) and force the epoxy into the knurling on the Bow Bolt and against the walls of the holes.

The male half of the Bow Bolt is the one with the “half hole” in the edge of the flange. It is best to orient the Bow Bolt with the male end in the bottom half of the bow and with the “half hole toward the back of the riser. Functionally, there is no difference, but with this orientation, the two parts of the bow will be closer to equal in length when the bow is separated, thus making it easier to pack for a trip.

One last note: The thickness of the wood “filler pieces” and the micarta shipped with your Bow Bolt may need to be reduced for a proper fit, but probably not by more than a few thousandths of an inch. A few strokes with 120# sandpaper is usually all that is needed, but at least be sure to lightly sand the surface of the micarta that will receive the epoxy before installing

Good luck, have fun, and please call if you have questions. (207-926-4133)

Craig

INSALLATION

1.

Determine location and angle of cut and cut riser. See photo #7.

2. For the ¾”

Bow Bolt, Drill ¾” X 1 ¼” deep holes in each piece of the riser opposite and

directly in line with each other. They must

be drilled perpendicular to the cut surface.

Or drill 5/8” X 1 11/32” holes for the 5/8” bow

Bolt.

3.

Tighten the joint to the stop and clean thoroughly. (Soaking

in Acetone is recommended)

4. Coat

surfaces in hole and on joint with MT-13 or Smooth on EA 40 and put some excess

in bottom of hole. Be sure to use FRESH epoxy.

5.

Insert joint into holes, line up riser and clamp squarely to

a rigid straight edge being sure the flanges are in tight contact with the

surface of the riser cut.

6.

Clean excess epoxy (that has squeezed out of the hole around

the flanges) after clamping. An

oversize “pipe cleaner” works well. Let

the epoxy cure for 24 hours before continuing. Low heat (under 120 degrees) may

be used to accelerate the cure time.

7.

After epoxy has cured, separate riser by turning ¼ turn

counter clockwise and pull apart. Check

to be sure that all excess epoxy (now cured) is removed from the surfaces

around the flanges. Use a small scraper

or sand paper, but be careful not to remove any riser material.

NOTE: Orient the Bow

Bolt closer to the back of the riser than the belly when possible, and leave

1/8” or more of riser material at the closest point to the Bow Bolt.

When the riser is reassembled and tightened to the stop with

the flanges tight together, there will be a gap of .120” around the flanges,

which equals the thickness of the two flanges. This gap will be filled with two

pieces of micarta, each about .060” thick and each with a 7/8” or ¾” hole in it

depending on the size of the Bow Bolt.

But for now, the gap must be filled with “scrap” wood to keep the excess

epoxy from the laminating process from filling it. The gap should be filled with two pieces of wood that have been

thicknessed to .060” each. They are

provided with the Bow Bolt. This will

provide a snug fit when the two halves of the riser are joined and should keep most

of the excess epoxy out.

At this point, lightly resurface the profile of your riser

and use it as if it were a one- piece riser in the construction of your bow.

When the bow comes out of the press, continue as you would

normally, including overlays, tillering, shaping and bringing the bow to

weight, but do not finish sand at this point.

SEPARATION AND MICARTA INSTALLATION

Using a hacksaw carefully cut through the belly and back of

the riser so that the blade cuts into the center of the scrap “filler pieces.”

Cut nearly all the way to the metal part of the joint, but be

careful not to cut into the Bow-Bolt itself.

Do this on the sides as well to remove as much of the filler

pieces as possible. Be careful not to

cut into the riser, just the scrap filler piece.

Cut on this

line.

When enough of the filler piece has been removed, you will

be able to twist the bow apart. Twist counter clockwise.

Pick out the rest of the filler piece and grind the

protruding overlay materials flush with the surface of the gap being careful

not to “round over” the edges of the gap.

ALTERNATIVE METHOD

An alternative method for installation is to

laminate the bow as you normally would for a one-piece, but when removed from

the press, leave the riser section with at least the belly and one side flat

and square to each other. These squared

surfaces will be needed for reference when marking and drilling for the Bow

Bolt, and for aligning the two halves when gluing in the bow bolt. Put on all overlays and then cut the bow as

in step one above. Now, CAREFULLY

mark and drill for the Bow Bolt.

This process saves a considerable amount of time

because the previous step of removing the filler piece and grinding the overlay

protrusion to the cut line is eliminated.

The drawback, however is that there is NO ROOM FOR ERROR when

drilling for the Bow Bolt, because even a slight miss-alignment of the holes

will result in the same miss-alignment of the laminations when the bow is

reassembled. I have used this method

successfully in retrofitting bows and will probably use it in new construction

from this point on and I would recommend it if you make a lot of bows. If you were only going to make one or two

bows with the Bow Bolt, I would recommend using the first method described.

Picking

out the filler piece

.

Grind or

file the overlapping overlay material flush with the original cut line.

Now dry fit the micarta pieces to check the fit. Closing the joint by twisting clockwise will

act as a clamp against the micarta pieces.

Be sure that the holes in the pieces of micarta are centered around the

flanges as you twist the joint together.

Dry fitting

the two pieces of micarta with their shiny surfaces together.

When the joint is twisted all the way to the stop, the

micarta should be snug, but not tight as there must be room for the epoxy.

When satisfied with the fit, take the bow apart and

reassemble after applying epoxy to the rough surfaces of the micarta and on the

wood around the flanges.

The micarta

pieces have been epoxied in place.

Use extra care not to get epoxy on the surfaces of the

flanges or on the shiny surfaces of the micarta or you will risk the

possibility of gluing the bow back together again.

When the epoxy has cured, grind away the excess micarta and

epoxy to the surface of the handle and finish shaping and sanding. Spray the finish coats with the bow together

as if a one piece.

Congratulations, you have just finished the best takedown

longbow available.

HELPFULL HINTS FOR

INSTALLING THE BOWBOLT

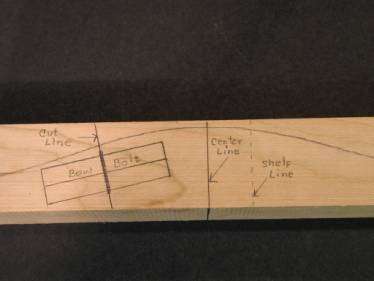

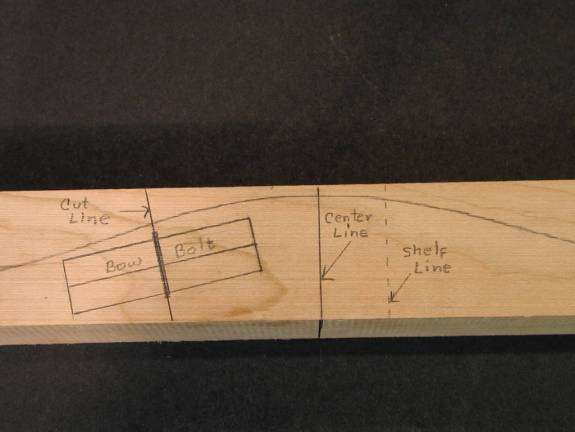

Layout

The Bow Bolt should be positioned in the riser block at a point where there will be the most riser material left around the joint when the riser is shaped. Refer to the picture below to see where I position the Bow Bolt in my style of riser:

The angle of the cut line to the riser block is determined by the position of the Bow-Bolt in the riser block. In this case it is a little less than 90 degrees from the belly side of the riser block.

The most critical part of the installation is in drilling the holes that accept the Bow Bolt. They MUST be drilled perpendicular to the cut line, and directly in line with each other.

I have found that, for me, the best way to do this is by

turning the drill press table vertically so that its surface is parallel to the

drill bit and then clamping the riser block to the table with the cut surface

square to the drill bit. By attaching a

straight edge to the table that is square to the bit, the riser block will

automatically align itself square to the drill bit. Be sure to clamp the riser block firmly to the table because

drilling in end grain may take considerable pressure. See picture of set-up on next page. The

hole depth should be about 1/32” more than the distance from the bottom of the

flange to the end of the Bow Bolt.

This picture shows a jig that accomplishes the procedure

described on the previous page. It

allows for drilling both holes simply by sliding the fixture over to the second

hole and re clamping, but simply clamping the piece to the table at the proper

alignment will work as well.